HFM foil sleeves

Vapour barrier foils are increasingly being used on floor slabs. Connection to the relevant building entries or media lines, however, is often not taken into account in advance, or is improvised. For the most common scenarios, the HFM foil sleeve from Hauff-Technik represents the optimal solution.

HFM foil sleeves

Hauff-Technik Air-Sealing Sleeves for Floor Slabs

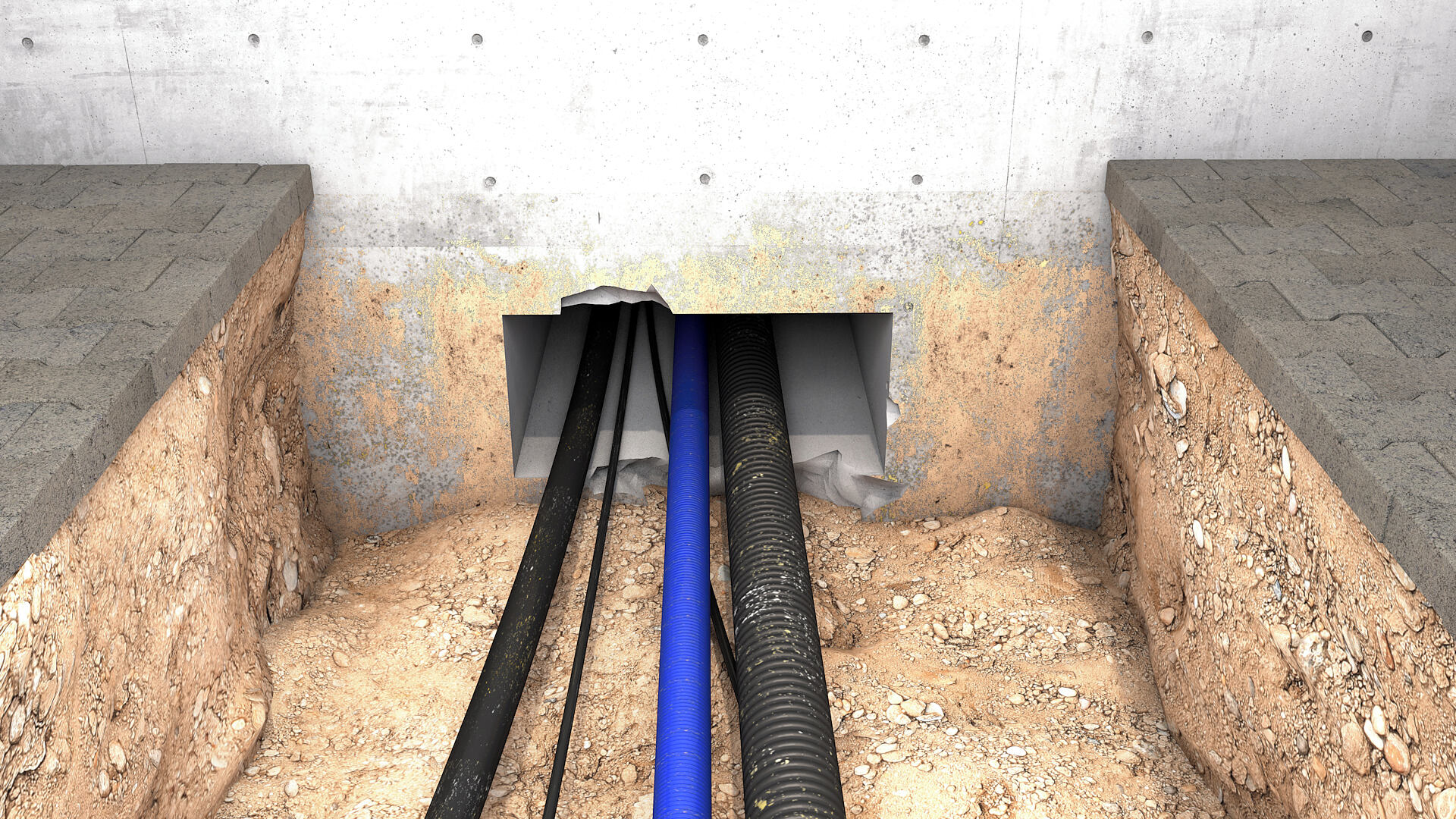

Entries in the floor area are particularly sensitive and require effective sealing against water and gas ingress. Modern buildings often necessitate specialized solutions, as vapor barrier films are frequently employed on floor slabs. Unfortunately, the absence of appropriate technology can lead to improvised measures, compromising the integrity of the building's seals. To remedy this, Hauff-Technik provides air-sealing sleeves specifically designed for these applications. These sleeves ensure reliable sealing of penetrations, effectively preventing moisture and gas infiltration.

Application Areas for Hauff-Technik’s Sealing Sleeves

Hauff-Technik has specifically designed air-sealing sleeves for the vertical entry of supply lines through floor slabs. It is essential to ensure an airtight transition into the building in this context. Vertical entries in the floor are particularly vulnerable to moisture ingress and also present a significant risk of radon exposure.

Hauff-Technik's air-sealing sleeves are classified under DIN 18533 W1.1-E, offering protection against ground moisture and non-pressurized water. When properly installed, these sleeves also prevent the infiltration of radon gas into the property, providing effective protection against potential hazards linked to the entry of supply lines through the floor slab.

These sleeves are versatile and suitable for various types of buildings, especially when the floor slab is sealed using vapor barriers, radon films, or other sheet options. They can also be employed for floors classified under WU concrete stress classes 1 and 2. Additionally, the sealing sleeves are ideal for sealing horizontal entries through walls, particularly in basement areas.

Variants of Hauff-Technik’s Air-Sealing Sleeves

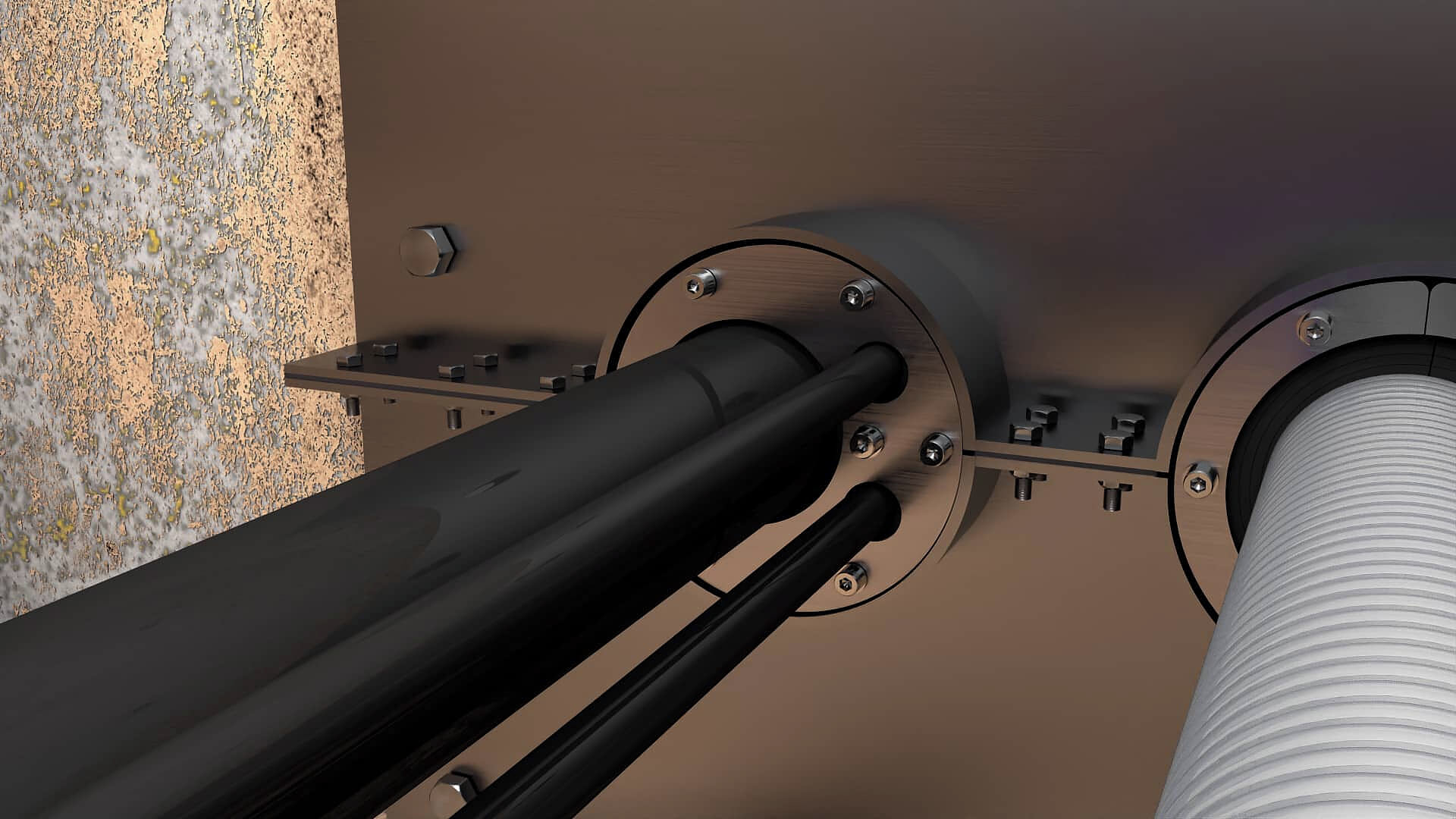

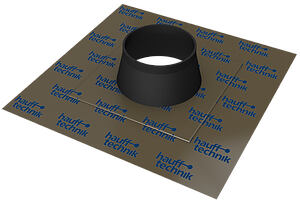

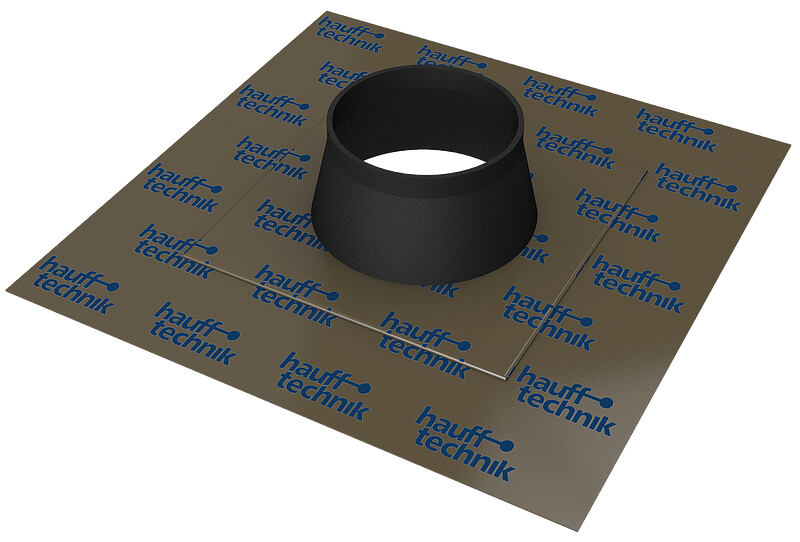

Hauff-Technik provides a range of options for air-sealing sleeves tailored to various applications. The HFM film sleeve is specifically designed for single penetrations, accommodating round supply lines, making it an all-around solution for numerous scenarios.

Additionally, there is an air-sealing sleeve that complements the MSH Basic FUBO SR4 multi-entry system. This system features a rectangular base, and the corresponding sealing sleeve is designed with a rectangular cutout.

These sealing sleeves are versatile and suitable for cables and pipes with different diameters. Hauff-Technik offers a broad selection of sizes, covering diameters from 4 mm to 250 mm. This ensures that there are precisely fitting options available for single-supply building packages, such as the ESH Basic FUBO BHPxm. The rectangular variant is specifically tailored to fit the MSH Basic module, with external dimensions of 750 x 320 mm.

Hauff-Technik solutions function as both cable sleeves and vapor barriers, eliminating the need for improvisation during the sealing of these floor penetrations. Their designs guarantee a secure seal that effectively prevents both moisture and radon infiltration.

Installation of the Air-Sealing Sleeve – Quick and Uncomplicated

Hauff-Technik offers various film sleeves that provide a simple and reliable sealing solution. A key advantage of these sleeves is their straightforward installation on-site. The film flange is made from an aluminum-plastic composite combined with butyl rubber, ensuring strong and long-lasting adhesive strength. When utilized as a sealing sleeve in the ground, the air-sealing sleeve adheres securely to the vapor barrier film.

To begin the installation, place the film sleeve over the supply line that needs sealing. This step also helps determine the appropriate diameter if it is unknown beforehand, allowing for the selection of the correct sleeve. The EPDM rubber insert ensures a tight fit around the supply line, whether it’s an electrical cable, pipe, or another type of penetration. The air-sealing sleeve is then pushed down to the floor slab.

After positioning, remove the protective film from the adhesive flange. Press this flange directly onto the vapor barrier film of the floor slab. The gas- and water-tight installation is completed with a pressing tool, which is available as an accessory from Hauff. This tool ensures that the adhesive flange is firmly pressed against the substrate for a secure bond. This creates a solid unit between the sleeve and the vapor barrier, ensuring a gas- and water-tight seal across the entire floor area. The entire installation process is tool-free and can be completed in just a few minutes.

Help us improve our website service.

Where would you place yourself?

Architect & designer

Wholesaler

Telecoms

Utility company

Installer

Construction company

Please choose your region

-

Belgium

Belgium

-

Česko

Česko

-

Danmark

Danmark

-

Deutschland

Deutschland

-

España

España

-

France

France

-

Global

Global

-

Hrvatska

Hrvatska

-

Italia

Italia

-

Luxembourg

Luxembourg

-

Magyarország

Magyarország

-

Nederland

Nederland

-

Österreich

Österreich

-

Polska

Polska

-

Schweiz

Schweiz

-

Slovenija

Slovenija

-

Slovensko

Slovensko

-

Sverige

Sverige

-

United Kingdom

United Kingdom

-

Global

Global

-

USA

USA

-

Global

Global

-

India

India

-

中国

中国

-

Global

Global

-

الإمارات العربية المتحدة

الإمارات العربية المتحدة